Laser cleaning is now the talk of the town in most industries, thanks to its effectiveness. Laser rust removal is one type of laser cleaning is an excellent cleaning process for metal parts. The most significant benefit of using fiber laser cleaning is the fact that it removes rust and other contaminants quickly without even damaging the material underneath. You can also do it by yourself by finding laser rust remover for sale.

Moreover, it’s cost-effective, and rust is removed with greater precision. Also, it’s arguably the best method that you can use to reduce the environmental impact. Generally, laser rust removal is an excellent alternative to chemical and manual cleaning methods.

Benefits of Laser Cleaning

Laser technology for rust removal is gaining traction lately, and for a good reason. Here’s what laser technology is capable of;

Environmental-Friendly

Unlike the traditional methods that use chemicals and consumables to remove rust, laser cleaning is on another level. In fact, it’s the sole method that meets the environmental protection regulations, meaning you can get rid of the consumables while you go green.

It generates relatively low dust into the air, which can be vacuumed almost instantly with only a dust extraction system.

It Eliminates Manual Labor

There’s no denying that cleaning every part of a metal manually can be expensive and inefficient. Therefore, laser cleaning eliminates such expenses as it’s either fully or semi-automated.

It Minimizes Maintenance

Abrasive blasting requires constant maintenance. The reason being, there can be several reasons, such as the presence of sand, meaning you must always be on the lookout. On the other hand, laser rust removal is essentially a non-contact process that removes rust continuously, reducing maintenance costs.

Safety

Operators are safe with laser cleaning as it’s non-contact; therefore, laser cleaning provides a safe workplace. Personal protective equipment is not required for hearing, respiratory, or even body protection. Besides, they don’t handle dangerous materials.

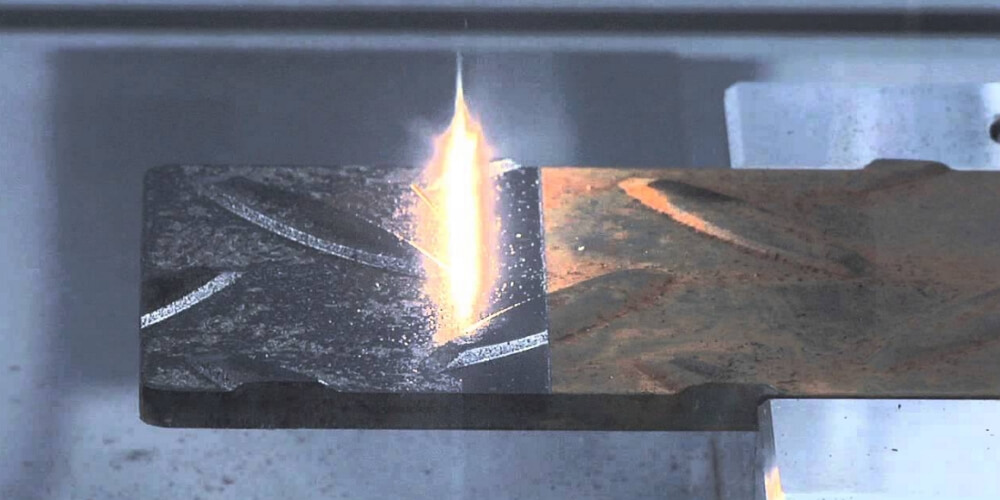

How Rust Removal Works

All materials have different characteristics that define the manner in which they can react in various conditions. It’s what’s known as the ablation threshold. The laser beam should be shone on the surface that’s being cleaned at an intensity below the material’s ablation threshold. After that, the energy is dispersed as heat when the rust has been removed.

What’s left behind is a clean surface, and the underneath surface is left unaffected. Rust is basically removed at speed, depending on the thickness of rust and the laser power.

Applications of Laser Cleaning

Laser cleaning is applied in several industries across the globe to perform several systems. For instance, it’s applied in pre-welding treatment, meaning it’s used in improving the quality of welded parts. When the dirt and rust layers are removed, porosities in welding joints are reduced, meaning welds have greater yield strength, ductility, tensile strength, and fatigue life.

Also, it’s applied in pre-coating treatment, whereby if you’re painting your parts, after welding them, the oxides should be cleared to prevent the coating from failing. Therefore, laser cleaning helps to remove rust to ensure that you acquire high-quality parts.

It’s crystal clear that laser cleaning is the method that is the way to go for the industries as it’s cost not only friendly but also efficient.