In the process of multilayer PCBs production, the material used is an extremely durable one. This means that 4-layer PCBs can withstand extreme working conditions and temperatures without wearing out or burning up. This material can be printed on top of conductive material which can be very thin, like paper, or it can be printed on the surface of other materials which can be thicker such as plastic or metal.

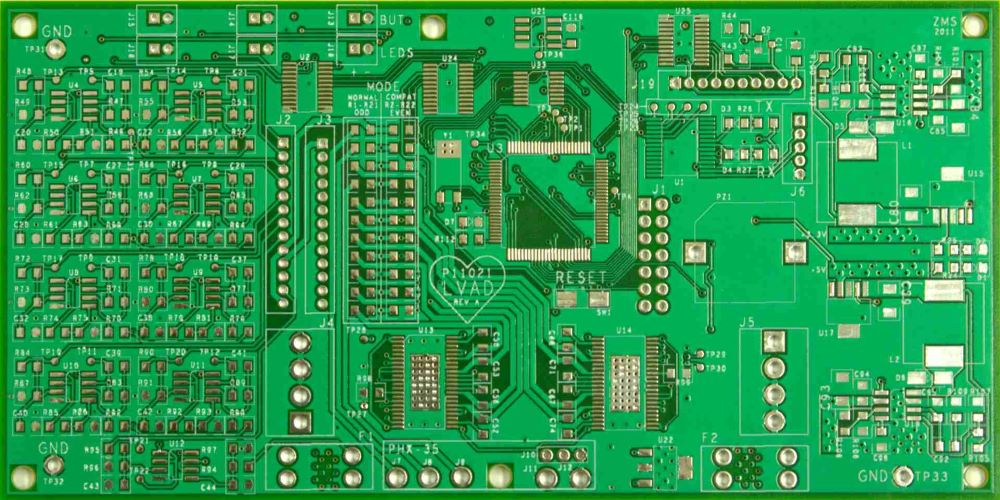

High-Quality Material of 4-Layer PCB

The thickness of these layers makes it possible for them to be stacked in the order that they want. If the boards are manufactured using flat-bed material, then they can be stacked in any order. However, when they are manufactured using roll process material, they need to be stacked in the order in which they are manufactured. You should remember that the thickness of these layers makes a huge difference in the durability of the product. So, you must be extra careful about the quality of the material that is used.

High-Quality Ink for High-Resolution Images

Another characteristic of this material is that the printed images on the board can be easily printed using high-quality inks. On the contrary, if the board is made using low-quality ink, then the images will have low resolution. You should not compromise on the quality of material for the printed images on the board. This will help you in saving lots of money while buying the product.

Use of Dot Matrix Technology

This board can be easily inserted into different printing processes. There are many types of printers that can readily print on the board using different ink. This means that it can be used with laser printers as well as inkjet printers. In addition, you can also make use of the dot matrix technology in the production of the boards. It has been found out that the result of the dot matrix technology is far better than the dot-free technology.

Cleaning Guide for 4-Layer PCB

Another characteristic of this material is that it can be easily cleaned using wipes or other materials. You should not use abrasive materials for cleaning the board as it may damage the image and the written content on the board. In addition, it will also reduce the lifespan of the printed information. This means that if you want to keep the printed material on the board for a longer time, then you should consider the characteristics of this material.

The flexibility of 4-Layer PCB

The characteristics of 4-layer PCBs include their flexibility to suit different types of business needs. When you are using this board, you can easily make the necessary changes in the design as it has open layers that are supported by interlocking tabs. You can easily drill holes and install hardware components. In addition, the material has an open surface that can easily be fixed with glue or soldering.

Use of 4-Layer PCB in Different Fields

The characteristics of 4-layer PCBs have made them more popular among manufacturers. You can easily use this board in the manufacturing of toys and electronic products. The material can be printed on the top layer and the bottom layer. Thus, you can use the product in toys and electronics manufacturing and even in office supply industries. When you are looking for a material that can be easily printed on the board, you should consider using a 4-layer PCB.