CNC parts play a vital role in the machining process. It is one of the main factors that determine the effectiveness of the process.

Having this in mind, this blog has been carefully prepared to provide readers with basic information about CNC parts.

Before going into that fully, it should be noted that CNC milling process adopts different applications. It also employs different machinery and machine tools.

Basically, the type of software or machine used for a particular milling process depends on the operation to be performed.

For the software, CAD software and CAM software is usually needed. While CAD software is used to initiate the design, CAM software is used for the generation of the main program.

After the program has been generated, it is transferred into the preferred CNC machine. On completion of the upload, the milling process is then initiated and executed.

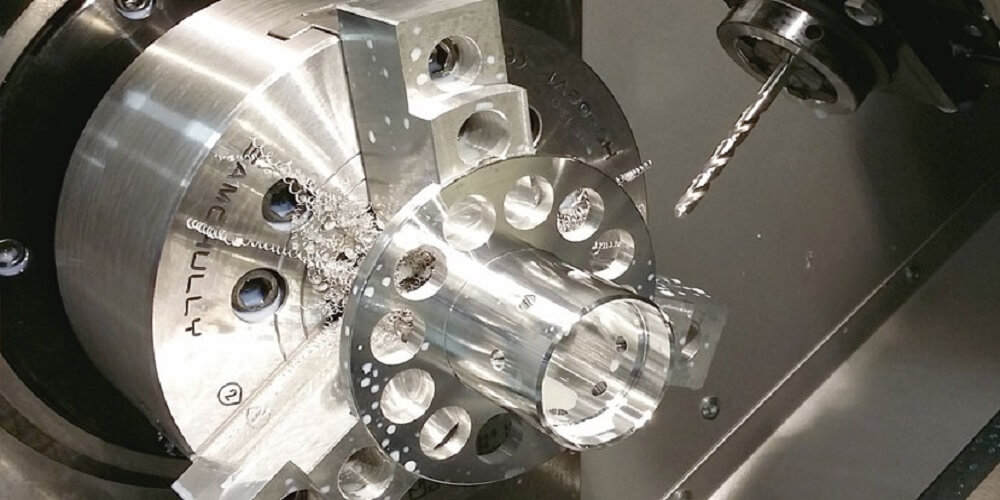

Major Components of a CNC Milling Machine

There are different types of Milling machines widely available. This notwithstanding, they all do share similar components. Some of them include

Machine Interface

It is part of the CNC milling machine used for loading. It is also used to start and run the machine program.

Column

The main function of this component is to offer support to all other components of the machine. It normally has an affixed base.

Sometimes, it comes with coolant reservoirs and oil. Coolant reservoirs are very necessary for the smooth running of the process.

Knee

This is another component that offers support to other components. It is flexible and fastened to the column. It enhances the performance of the saddle and worktable by offering support. The knee can be lifted or lowered.

Saddle

The saddle is that part of the machine placed on top of the knee. It also offers support to the work table. It can move in a parallel direction towards the spindle.

This arrangement makes it possible for the worktable and the workpiece to be placed horizontally.

Worktable

It is found on top of the saddle. It is used for fastening the workpiece. The design of the worktable differs from machine to machine.

Some can be adjusted horizontally while some can be adjusted vertically. In some cases, it can be adjusted both ways.

Spindle

The column helps to keep this part of the machine in place. It is with the help of the column that the spindle rotation is made possible. An electric motor is employed to rotate the spindle.

Arbor

This component is usually found in a horizontal milling machine. It is the shaft component placed in the spindle. While some are longer, others are usually shorter. The diameter of the Arbor to be used also varies.

Different Types of Arbors include shell end milling cutter arbors, slitting saw milling cutter arbor, screw, and standard milling machine.

Ram

This part is normally found in vertical milling machines. It is located above the column which serves as a backbone for the spindle.

This component is easily adjustable. It can be adjusted to accommodate different levels during operations.

Conclusion

No part of a machine, even the tiniest part is insignificant. Every part has a vital role to play to ensure the efficiency of the machine.

Hence, you should ensure that every part of the machine is taken care of. This is one way to guarantee the success of every operation.