Warehouse operations can be improved in different aspects to ensure efficiency and productivity. The activities taking place in the China fulfillment warehouses revolve around picking, storing, moving loads around, and transporting. Therefore, there is a need to invest in equipment that can help achieve efficiency and facilitate easy material handling.

Keep in mind that businesses will consider the quality of your warehousing facilities before they opt to work with you. Warehousing equipment will have a significant impact on every operation, polarize experience and define potential benefits. The equipment will range from those that will improve warehousing practices to technological advancements to provide solutions in various aspects. As such, you need to beware of the appropriate equipment that can help achieve your warehousing requirements.

This guide provides insight and essential factors to consider when choosing warehousing equipment.

Evaluate your warehousing objectives

Warehousing services could differ depending on the products you are handling. It is essential to understand the specific objectives of your warehouse before choosing any piece of equipment. You will definitely understand what the equipment is needed for once you clearly define your motives and warehousing requirements.

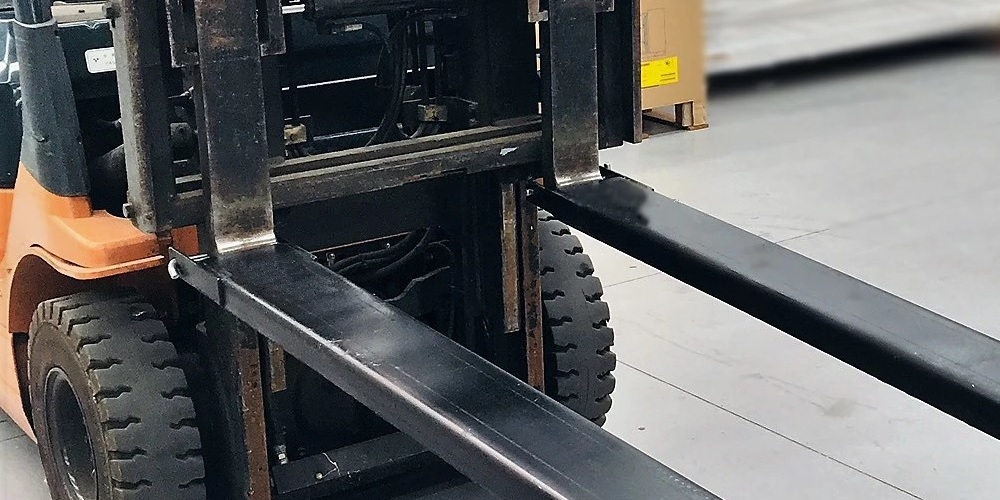

The equipment you may require for your warehouse could maximize your space, accommodate the high demands and increased product flow, or run operations like packaging, loading, moving products, among others. Keep in mind that the equipment available in varying capacities; therefore, you should be keen to select those that meet the specific needs of the warehouse.

Opt for professional input

Whether you are starting new warehousing services or redesigning the existing operations, choosing the correct equipment can be challenging and complex. If you are not sure of the equipment that fits your niche margins, it is advisable to seek a professional to provide insights and inputs. Professional consultants will help you analyze your motives, warehouse designs, and layout, operations, activities, and processes at the site. This will be helpful to determine the correct equipment that will maximize efficiency and profitability as well as accomplish your goals.

Training and maintenance requirements

When you consider investing in new warehousing equipment, you need to understand the training requirements. While you may be having a user manual, evaluate the time you will spend training your employees and associates on the new equipment. Some equipment such as technological devices might require expert knowledge to put them on board.

It is essential to check whether the vendors are offering training services and 24/7 support regarding the equipment. Ask questions to know whether you need a special license, continuing education for the equipment, and whether it may have safety compliance issues. Besides, you need to know the maintenance requirements and costs before you purchase the equipment.

Process and customization needs

It would be best if you considered your approaches to different processes in the warehouse. It is a crucial factor to identify the type of equipment required. You will need pieces of equipment that can be customized for compatibility purposes. Some processes might require heavy-duty machinery and may require regular maintenance to keep processes at their optimal levels. You need to think about the best solutions, such as automated technology, to maintain possible customizations and support for the equipment you want to purchase.