Once an idea gets its final version, the next logical step is to choose the materials and the manufacturing method. If we follow modern trends than the logical choice is aluminum as a material and some type of aluminum fabrication method. Fortunately, nowadays it’s pretty easy to find a reputable aluminum machining service that will bring your prototype to life.

Here are the top five reasons why aluminum as a material and aluminum fabrication are so popular among inventors and product builders.

Reasons Why Aluminum Fabrication is Popular

1. Aluminum has excellent conductivity

Copper might be the most widely used material for electrical appliances and wiring, but copper is expensive and soft. On top of it, its corrosion resistance is low.

Aluminum is better than copper in each of those scenarios and is evenly conductive as copper. Therefore, it makes perfect sense to use it for an electrical device prototype.

2. Great surface finish and precision

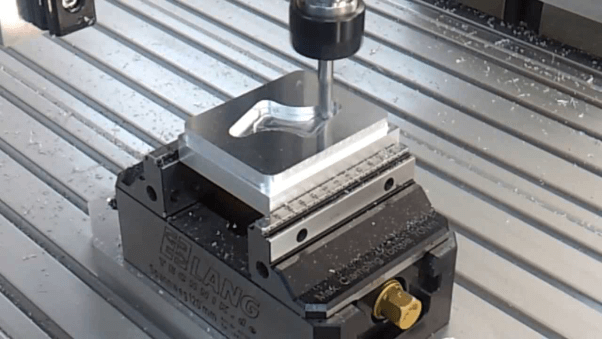

Custom aluminum fabrication uses CNC machining which means there is no need for any melting or consecutive solidification. That’s important because melting and solidification inevitably lead to distortion.

The top aluminum fabrication tolerance is IT8-7, while the surface finish can be RA 1.25 mcm.

3. Corrosion resistant

Aluminum’s corrosion resistance properties are well-known to all experience manufacturers, engineers, and innovators. Aluminum, as a material, wouldn’t be held in this regard if it wouldn’t be for its corrosion resistance properties.

If corrosion plays a big role, then choosing aluminum solves that issue once and for all. The thing is, aluminum forms an oxide screen on its surface which cannot be noticed by the naked eye. That protects the metal from harmful agents and keeps it corrosion-free. There is no need for any additional paint or coating to prevent it from getting rusty.

4. Aluminum doesn’t react to magnets

Aluminum is a non-magnetic alloy that is immune to the surrounding magnetic field. This characteristic is also present in other alloys, but aluminum is the strongest and cheapest of them all.

That makes aluminum perfect for enclosure of some fixture or device that doesn’t need to be magnetized.

5. Easy to recycle

All modern industries pay a lot of attention to eco-sustainability and pollution. They all want to reduce their carbon footprint to as little as possible.

As a result, we are seeing a decline in the use of plastics and polymers. After all, recycling plastic, especially industrial grade type of plastic, is a costly and complex process.

On the other hand, aluminum is easily recycled in full.

Conclusion

There are dozen or more reasons why aluminum is so popular and why everyone is in love with aluminum fabrication. But going through each one of them will take quite some time and the final conclusion will be identical as this one – one can rarely go wrong with aluminum.

The only trick is to find an experienced manufacturer that knows his way around aluminum and is enough skillful to turn your sketches and idea into a physical product.