As the adage goes, there is always more than just a single way to skin a cat. That is why it is reasonable to point out that there are more than two types of industrial spark blades. Even for the well-known pocket knives, they come in a variety, and note, this isn’t just a stance, nor is it a whim of imagination.

Thus, industrial blades come in different shapes for various reasons. Below is vital information regarding the common types of blades used in mass production.

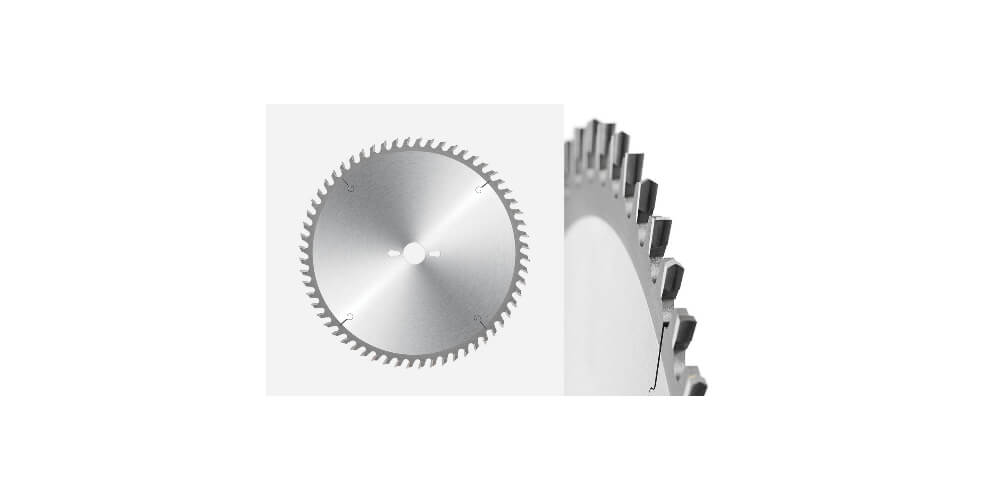

1. Round blades

Circular blades are made from steel, and rockwell hardness comes in diameters of up to 300mm. The inner diameter is approximately 200mm, and they have two-sided compound levels. Lastly, the mounting holes are drilled upon the request of a client.

2. Pointed tip blades

Whether you have a rough sketch or idea that needs to be transformed into a cutting edge, pointed tip blades are capable of cutting your materials into the required sizes. The custom industrial machines are for cross-cutting, press cutting, and die-cutting, among others.

In high-end facilities, pointed blades make custom precision wear parts like industrial blades, for converting industries and custom medical knives for mass production. Industrial experts use top-notch grade hardened tools for the applications.

3. Toothed blades

These knives are also known as packaging saw blades. Their timely change is essential in making sure that the tool cuts with precision without having to damage the workplace.

The blade can also be used to reduce injury to an operator. This means that if you would like to buy a replacement blade, you should consider the model of saw coupled with specific cutting needs as well as applications.

Take-away

- Used for packaging

- Custom length

- Part number – 1031

- Made from high speed steel

4. Curved blades

Curved blades are knives with some angle of curvature any time it is viewed from a specific side. As a new design on the market, the blades are better than the straight ones. Even so, they still come with a few drawbacks such as the cost of ownership as well we longevity. Curved blades have a strong design that does not wear out quickly. This distinctive feature makes it a preferred industrial knife for most consumers.

5. Toothed Blades

Do you want to cut a product into a zigzag shape such as crisps? Or would you like to make clean cut longitudinal lines in the raw material? If your answer is yes, then you can always use toothed blades for your project. A toothed blade can dice high-grade materials, with wider choices, but it is also adaptable.

Final Thoughts

When it comes to selecting the right blade for your industrial needs, you have major decisions to make. If you are going to cut metal materials, then you need to invest in high-quality tools such as toothed blades. Whatever it is you decide to utilize, selecting the right blade for the application is a crucial step. Because there are multiple brands on the market, choosing the best can be a daunting task. That is why, after extensive research, this blog post shares some of the best types of cutting blades for your project. Happy shopping!