A gold melting machine is a piece of jewelry-making machinery. At high temperatures, it liquefies gold and other valuable metals, becoming them pliable and simple to manipulate. When purchasing a gold melting machine, it is essential to understand how it operates and what features to look for.

If you want to create your own gold jewellery, you need understand how a gold melting furnace works. This will assist you in crafting the ideal piece of jewellery or another object.

Here are the several principles you should be aware of:

Working according to the concept of resistance:

Most gold melting machines employ resistance heaters to create the appropriate temperature for melting gold bars or other precious metals. Resistance heaters are sometimes referred to as induction coils or coils because they produce an electromagnetic field that warms metal objects put on top of them.

Using the heating mechanism of induction:

Modern gold melting machines use induction heating to melt precious metals such as silver, platinum, and palladium. The induction heating technique use high-frequency alternating currents to produce magnetic fields that heat the metals put above them. This technology is superior to others for melting precious metals because it needs less energy than resistive heating devices and generates less waste heat during operation.

Working on the microwave heating concept

The gold melting machine may be used to melt gold in the creation of jewelry, including fine jewelry, watches, and other jewelry. It is extensively used in the electrical, medical, and precision instrument industries. The process for melting relies on microwave heating technology. The microwave heat produced by the magnetron tube raises the temperature of the material inside the crucible to around 1,000 degrees Celsius. When the substance reaches this temperature, it melts and becomes liquid. Then we may pour it into different molds according on our requirements.

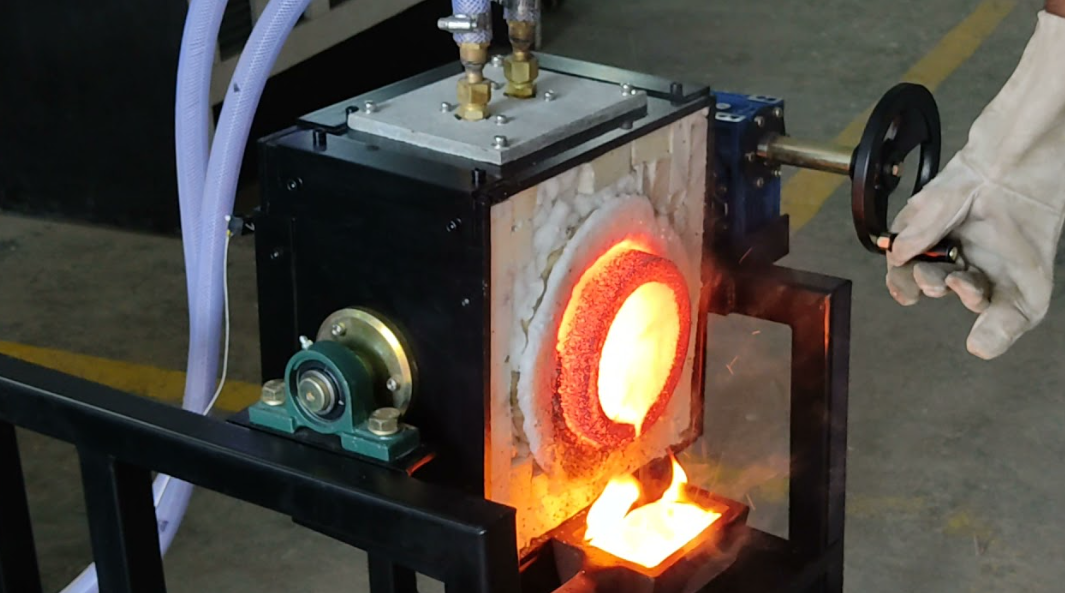

Fundamental Elements of a Gold Melting Machine

These include:

- Melting Chamber – The gold is melted in this chamber. A multitude of vents let air to enter and depart during the melting process.

- Heating Elements – These are used to heat the crucible and, depending on the design of the machine, are situated in various locations.

- Crucible – This is where the gold bars are placed before to melting. It should be constructed of materials that can sustain high temperatures without decomposing or warping. Quartz, graphite, silicon carbide, and boron nitride are used materials.

- Theburner – It provides heat to your crucible, allowing you to melt many sorts of precious metals into a liquid state. Electric and gas-powered burners are both available for use with gold melting devices. A gas-powered burner utilizes propane gas as its major fuel source, while an electric burner uses electricity as its primary fuel source (although some models may also use electricity).

Conclusion

When dealing with molten gold, extreme caution is necessary. Each machine is constructed according to the specific needs of its users and has its own functioning principles, parts, and components. In numerous chemical industries, the jewelry industry, and investment casting foundries, gold melting machines are used. Such devices include electron beam melting furnaces, plasma arc melting devices, induction crucibles, jet nozzle devices, and vacuum induction melting devices, among others.

You may also need to remember the basic components in these machines also affect the entire functionality of the machine and the output result you get from them. So when buying them, be cautious of what you go for.