Pressing is used to flatten, bond, and veneer metal sheets into various shapes and forms. The shapes and forms are generally pre-determined. Hydraulic pressing is one of the primary forms of pressing. Hydraulic pressing uses fluid as the operating mechanism. These presses can be categorized further into hot and cold hydraulic presses. Hot and cold presses are efficient and bonding methods of pressing metal sheets. This post discusses the differences between hot and cold hydraulic pressing.

What is hydraulic cold pressing?

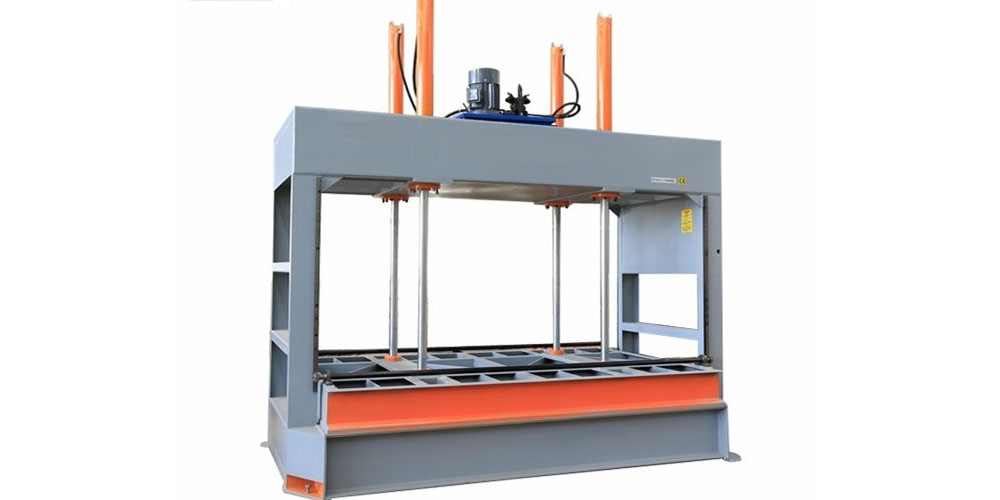

The primary defining characteristic of cold pressing is that it is done at room temperature. The cold-pressing process typically takes a long time (between three to four hours or more). For this reason, factories that use cold pressing as a primary manufacturing technique require several machines to work simultaneously, so they do not have to wait for hours to get work done.

Cold pressing is primarily applied in the production of wooden products like doors and panel cabinets. In cold hydraulic processing, pressure is applied to manufacture various products from a wide range of materials. A cold hydraulic press machine is usually placed on stable ground. It also features a temperature monitoring device. The role of the gadget is to ensure that the temperature does not rise above 70 degrees, depending on the application. A temperature switch is also applied. The switch is used to control and set the temperature. The switch can be turned off the heat once the appropriate temperature is reached.

What is hydraulic hot pressing?

A hydraulic hot press machine plays a significant part in manufacturing various aircraft components from metals, like titanium and stainless steel alloys. The defining characteristic of hot pressing is that it is done at high temperatures of around 300 degrees. Hot pressing helps produce more accurate parts.

In hot pressing, the metal or metal alloy is heated in the press to a superplastic state. It is then formed thanks to a controlled hydraulic pressure. The superplastic material is transformed into various shapes and structures based on the machine and application. Note, hot hydraulic pressing can be used for forging and extrusion applications. It is also worth mentioning that hot presses are usually made up of furnaces that apply heat to the material. The furnaces also help provide the pressure used in the forming process.

What is the difference between the two?

Both cold and hot hydraulic pressing machines work by Pascal’s law. Pascal’s law states that the pressure applied to 1 point of a liquid is transmitted equally to all liquid parts. The two types of hydraulic presses also use fluid as their operating mechanism. However, they have one primary difference. The difference is that cold presses operate at room temperature while hot presses feature elevated temperatures of up to 300 degrees.

Take Away

Note that another difference between cold and hot hydraulic pressing machines lies in their areas of application. Hot pressing is also substantially faster than the contrary. Regardless, both methods are ideal for various manufacturing applications.