The free-leveling 3d printer kit world is quickly evolving into a life-changing sector. And now that the printers are cheaper to produce, most experts have predicted that it shall not be long before these devices are conventional in homes. Today, more firms have realized that there is a potential for 3D-printed applications in business.

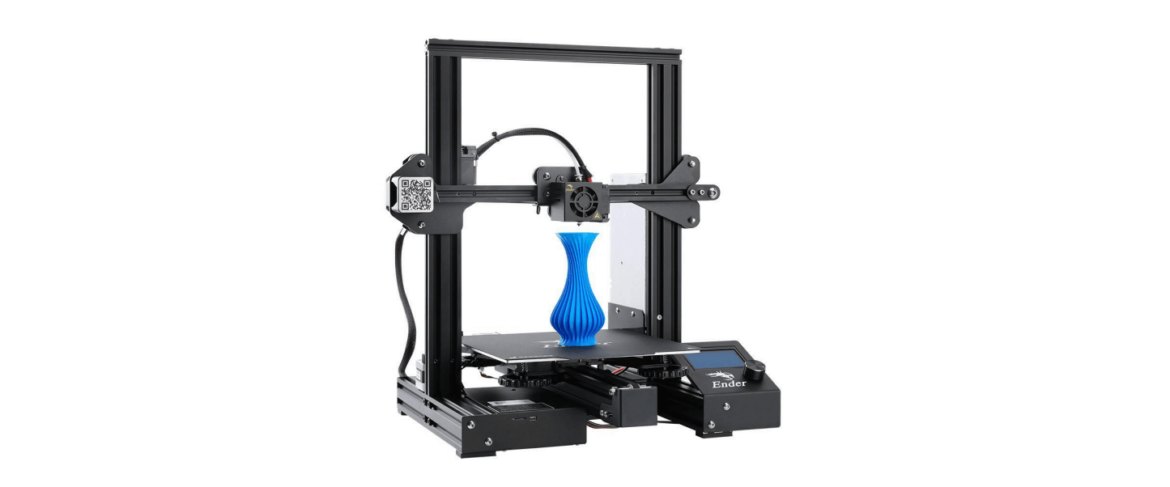

Since the technology moved from the fundamental theoretical to reality, people have been expanding their territories based on what printing can deliver from various practical applications. The manufacturing sector and the medical industry are quickly growing to accommodate the idea. But what about 3D free-leveling printer is interesting? Please follow along as we discuss basic 3D printer leveling.

The Back Story

3D printing started in the 1980s when one man known as Chuck Hall decided to design a small cup. The additive manufacturing objects are created from a digital file that lays down various successive layers of elements until when the object is fully complete. Typically, every single layer is identified as a thinly sliced section of the object. It’ll use a few pieces of materials as compared to traditional manufacturing. In multiple cases, the materials used in the 3D printing world are thermoplastics.

This is a type of material becomes liquid plastic when it is heated. However, it will solidify immediately after cooling down. In this case, it will not be weakened. But, as the technology matures, the researchers are finding out that there are new materials that can be printed as well.

Learning More about Auto-Leveling

The magic in 3D printing is found in the filament. Therefore, the material will always behave predictably at specified temperatures, thereby making it possible for you to control the form while making your 3D printed element possible. There are different things you need to consider when using a 3D printer. This is solely based on acquiring a successful print.

Typically, a level 3D print bed is essential in the whole process because it allows the material to extrude evenly from the build surface. After some leveling, you should adjust the height of the Z. At first, this should be done manually to balance the filament flow coupled with the bed adhesion. After that, you need to set some value in the software for the printer to know that there is a gap between your nozzle and the build plate.

So, do you need the bed-leveling? Yes, you need a level build surface.

It would help if you had a build plate that shows some consistent layer. Here are a few signs that you need one:

- The filament height varies across your machine’s build surface.

- The prints happen to warp upwards where they would not.

- The filament sticks to your machine’s build surface, especially in some places.

Final Thoughts

If your bed is unleveled, the auto-leveling 3D printer should make a few minor adjustments to ensure that your print bed and the nozzle are at a reasonable distance. This should improve your bed adhesion coupled with the printing quality.