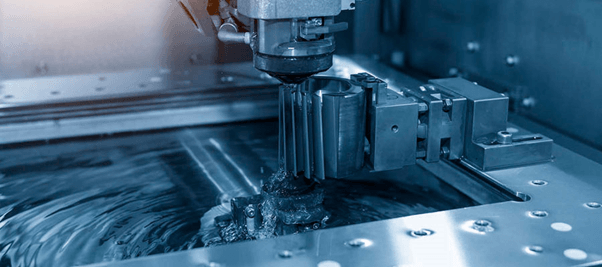

The machining world is quickly evolving. That is why we currently have the Electrical Discharge Machining, which is also known as EDM machining or die sinking. By definition, this refers to a manufacturing process in which the shape of a product is usually obtained using various electrical discharges known as sparks. In this blog post, the focus on EDM is directly impactful on the cost of machining titanium.

The material used is often removed from the centerpiece using a broad series of recurring discharges between two significant electrodes. One of these electrodes is known as the tool-electrode. The other is termed as the workpiece. Usually, the whole process is dependable on the tool as well as the workpiece, which does not make actual contact. In this blog post, we disintegrate the entire process of EDM Machining.

Background Look

During the EDM machining process, when the voltage found between the two electrodes is increased to some point, then the volume and impact of the electric field found between the electrodes will become more significant than the intense strength and effects of the dielectric.

As a result, this will break down and allow the current from the machine to flow from one electrode to the other. The phenomenon is actually the same in the case where there is a breakdown capacitor or, rather, a condenser.

Perhaps this is the first time you have heard the term EDM machining. But, rest assured that this discipline has severally touched your areas of life in one way or another. The precise elements of a medical device and the components of a jet engine or a nickel alloy are just some of the tenets involved in this subject. If a field manufacturer is in demand of different parts that fit tightly together, or just a few pieces designed and made up of robust materials, then EDM is one unique way to go.

Conventional milling using a machine involves the application of different materials and forces against the actual workpiece. The EDM product line manager in charge of most of the service and product delivery projects will reiterate to you that EDM is a viable machine tool maker.

And while in most companies, the staff may not be there physically to work on the parts it is always possible to do the machining using lightning bolts. Besides, the metal is hell. To be more specific, we are looking at the release of several sparks.

In this case, even the blade in that EDM machine is superfine in many cases. Although the device is cutting through sturdy materials like carbide, the blasts of power and electricity used are pretty much weak. Still, the blasts can come with high frequency, which is something that sparks every second.

Final Thoughts

Finally, it is crucial to understand that EDM machining has a different theory. One spark will not really erode the metal. To be more effective, EDM machines can fire millions of times in one second. The frequencies and voltages control the efficiency of these machines. That is why manufacturers keep the secrets closer to their chests.